язык

Понимание пленки EVA и ее состава

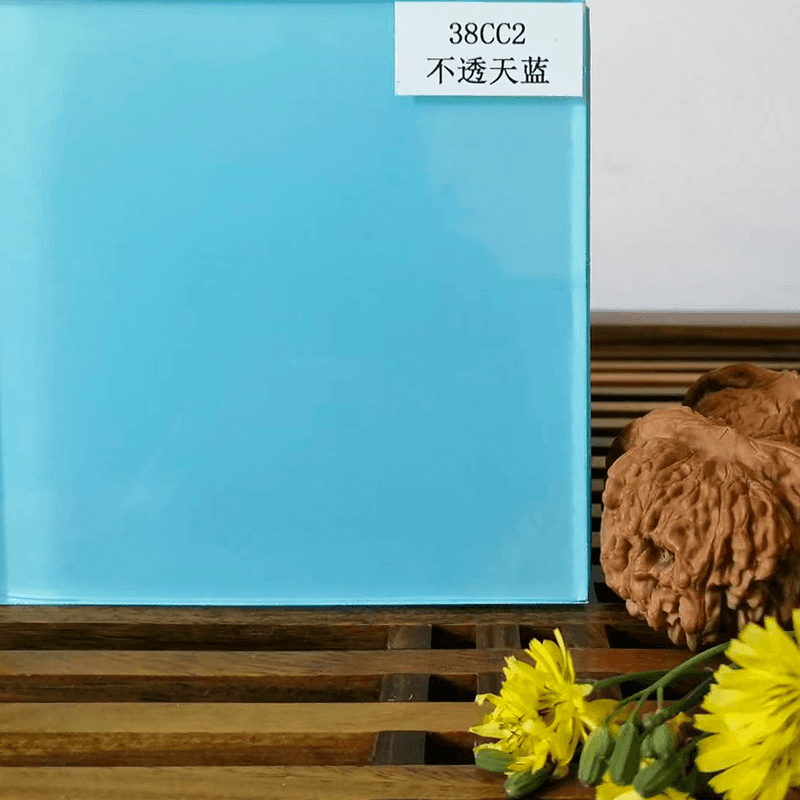

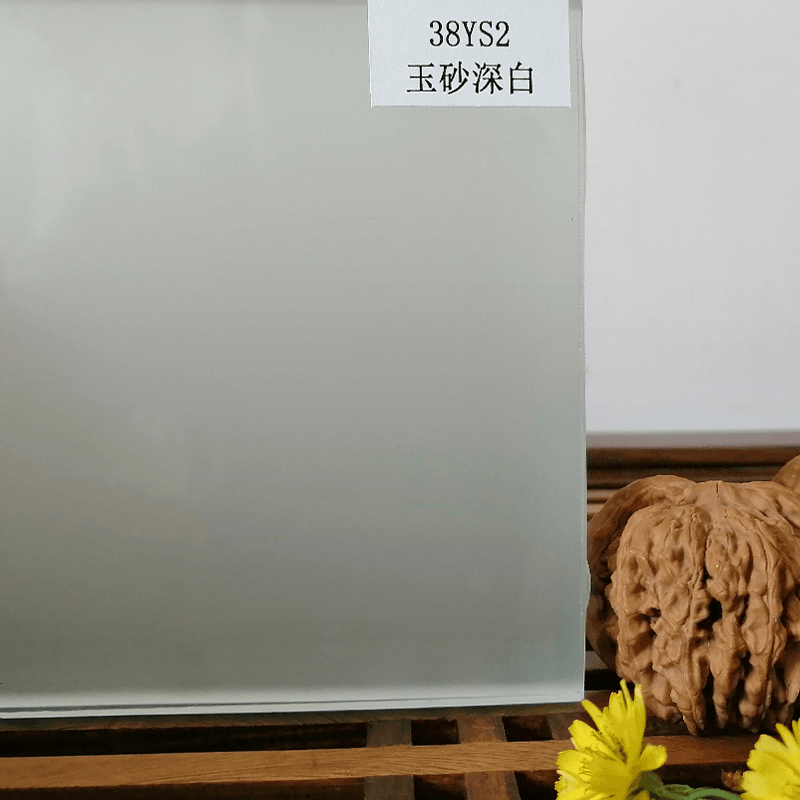

Пленка ЭВА (этиленвинилацетат) — универсальный полимерный материал, широко используемый во многих отраслях промышленности благодаря своей долговечности, прозрачности и адгезионным свойствам. Он состоит из сополимеров этилена и винилацетата, которые обеспечивают эластичность, прочность и химическую стойкость. пленки EVA часто производятся в листах разной толщины в зависимости от конкретного промышленного применения.

Высококачественные пленки EVA не содержат примесей, обеспечивая оптимальные характеристики при применении в ламинированных конструкциях, герметизации солнечных панелей или упаковочных решениях. Низкотемпературная герметизирующая способность материала и отличная устойчивость к ультрафиолетовому излучению делают его идеальным для использования как внутри, так и снаружи помещений.

Ключевые области применения пленки EVA

Уникальное сочетание свойств пленки EVA сделало ее популярным материалом во многих отраслях промышленности. Понимание этих областей применения может помочь производителям и конечным пользователям выбрать правильный тип и толщину для их конкретных потребностей.

Инкапсуляция солнечной панели

Одно из наиболее распространенных применений пленки EVA — фотоэлектрические (PV) солнечные панели. Пленка действует как герметизирующий слой между солнечными элементами и стеклянным покрытием, обеспечивая механическую защиту, электрическую изоляцию и устойчивость к влаге. Благодаря превосходной адгезии солнечные элементы остаются на месте на протяжении всего срока службы панели.

При выборе пленки EVA для солнечных панелей решающее значение имеют такие факторы, как индекс плавления, содержание винилацетата и толщина. Высокое содержание винилацетата улучшает гибкость и адгезию, а постоянный индекс плавления обеспечивает равномерное ламинирование.

Упаковка и защитные слои

Пленка ЭВА широко используется в упаковке, особенно для продуктов, требующих защиты от влаги или амортизации. Его гибкость позволяет ему принимать различные формы, а прозрачность делает его подходящим для розничной упаковки, где важна видимость продукта.

- Упаковка пищевых продуктов: сохраняет свежесть и продлевает срок хранения

- Упаковка для электроники: обеспечивает антистатические свойства и ударопрочность.

- Медицинская упаковка: обеспечивает стерильное и безопасное хранение.

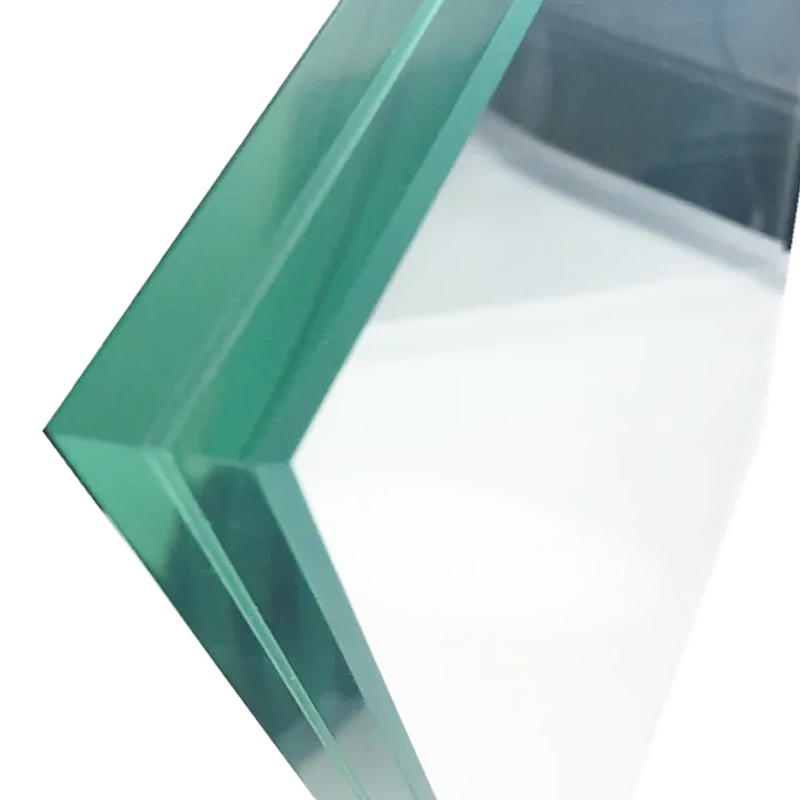

Ламинирование и композитные материалы

Пленки EVA широко используются в качестве ламинирующего слоя для гибких материалов, таких как текстиль, пластиковые листы и фотоэлектрические задние листы. Во время ламинирования EVA плавится под воздействием тепла и давления, скрепляя слои, сохраняя при этом прозрачность и гибкость. Это обеспечивает долговечность композитных материалов, подходящих для промышленного и потребительского применения.

Преимущества использования пленки EVA

Пленка EVA обладает множеством преимуществ, которые делают ее более предпочтительной по сравнению с другими полимерами в промышленном применении. Понимание этих преимуществ может помочь компаниям оптимизировать производительность и долговечность своей продукции.

Долговечность и устойчивость к ультрафиолетовому излучению

Пленка EVA сохраняет свою структурную целостность даже при длительном воздействии солнечных лучей. Его устойчивость к УФ-излучению предотвращает пожелтение, растрескивание или потерю адгезии, что делает его идеальным для наружного применения, например, для солнечных панелей или защитных покрытий.

Влага и химическая защита

Пленки ЭВА служат надежным барьером от влаги, пыли и некоторых химикатов. Это делает их очень подходящими для упаковки пищевых продуктов, герметизации электронных устройств и многослойного безопасного стекла, защищая внутренние компоненты от вредного воздействия окружающей среды.

Гибкость и простота в обращении

Гибкость пленки EVA позволяет ей принимать различные формы и поверхности без растрескивания. Он также легкий, что упрощает обращение и установку во время производственных процессов или применения на месте.

Советы по выбору и установке пленки EVA

Выбор подходящей пленки EVA и правильное ее применение могут существенно повлиять на качество и срок службы продукции. Ниже приведены основные соображения и рекомендации по установке.

Выбор правильной толщины и класса

Пленки EVA имеют толщину от 0,3 мм до 1,5 мм и более. Для солнечных панелей обычно используется толщина 0,45–0,6 мм, чтобы сбалансировать гибкость и защиту. Для упаковки может быть достаточно более тонких пленок, тогда как для ламинирования часто требуются более толстые листы для обеспечения долговечности.

Правильный процесс ламинирования

Во время ламинирования пленки ЭВА требуется точный контроль температуры и давления. Перегрев может вызвать пожелтение или образование пузырей, а недостаточный нагрев препятствует надлежащей адгезии. Типичный диапазон температур ламинирования составляет от 140°C до 160°C с контролируемым давлением для обеспечения равномерного склеивания.

Рекомендации по хранению и обращению

Для сохранения характеристик пленки EVA следует хранить в прохладном, сухом месте, вдали от прямых солнечных лучей. Листы следует укладывать ровно, чтобы предотвратить коробление и деформацию. Работа в чистых перчатках снижает загрязнение и сохраняет качество клея во время ламинирования.

Сравнение пленки EVA с другими материалами

При выборе полимерной пленки понимание преимуществ EVA по сравнению с альтернативами может помочь в выборе лучшего материала.

| Недвижимость | Ева Фильм | Полиэтилен (ПЭ) | Поливинилбутираль (ПВБ) |

| Устойчивость к ультрафиолетовому излучению | Высокий | Средний | Средний-High |

| Гибкость | Высокий | Средний | Средний |

| Адгезия | Отлично | Низкий | Высокий |

| Прозрачность | Высокий | Средний | Высокий |

Заключение

Пленка EVA остается универсальным и практичным материалом для промышленного и потребительского применения. Его превосходная адгезия, устойчивость к ультрафиолетовому излучению, гибкость и защита от влаги делают его незаменимым в солнечных панелях, упаковке и процессах ламинирования. Выбор правильной толщины, марки и метода установки обеспечивает максимальную производительность и долговечность, обеспечивая долгосрочную выгоду как производителям, так и конечным пользователям.